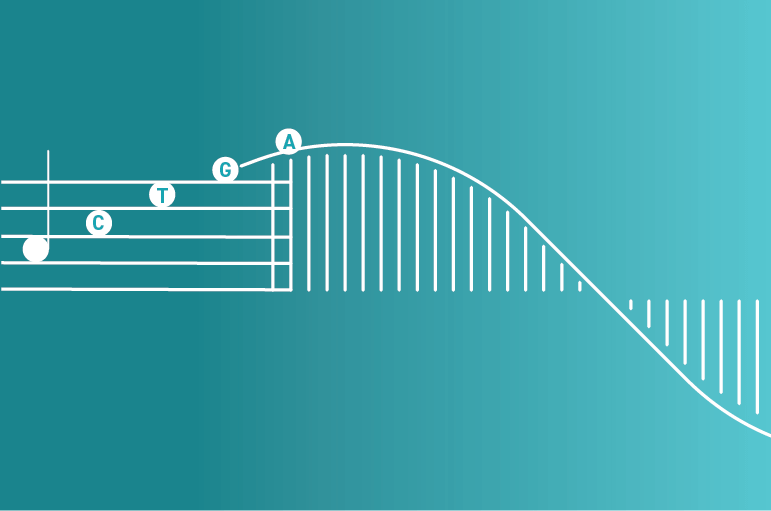

LR: In which fields does Twist’s technology provide particular benefits?ĮL: As DNA is a raw material and we service so many applications, it’s hard to distill it down. We firmly believe that this is just the beginning, as when you produce raw materials at a lower cost and make a lot, people find creative ways to use them. Today, we generate precisely synthesised Variant Libraries for antibody discovery, highly uniform target capture panels for NGS, Oligo Pools with oligos up to 300 bases, Antibodies against hard to drug targets, Cloned Genes, and Gene Fragments at industry leading prices and quality, and recently, positive RNA Controls for COVID-19 testing. In 2015, we launched our first product, Synthetic Genes. Starting with the highest quality raw materials affords us the flexibility to produce outstanding quality products. We find that the uniformity and quality of oligos manufactured in this way are exceptional. These form the raw materials for the rest of our products. In the same form factor as a plastic 96-well plate commonly found in labs, our proprietary DNA writers then make a million high-quality DNA oligos simultaneously, in a single day. We manufacture the proprietary silicon surface in-house, reducing our costs, ensuring we could pass those savings down to the scientists using our tools. Twist’s key innovation was taking that chemistry, miniaturising it, and putting it on silicon. LR: Describe Twist’s silicon-based DNA synthesis platform.ĮL: The chemistry needed to build DNA is well known the Bills didn’t invent that, but we have made some optimisations. We had a successful Initial Public Offering (IPO) in 2018, and that helped fuel our growth. That economy means grant and investor money can go further, and labs can explore more with the same budget, ultimately pushing the envelope on what is possible. We introduced DNA at 7-9 cents a base, and we can produce it in tremendous quantities. If we could produce more DNA and significantly decrease the costs, we could enable more research. It slowed productivity as researchers weren’t spending their time collecting and observing new data underpinning important discoveries, instead they were stuck building things. At Twist, we often say, ‘Friends don’t let friends clone’ researchers had to spend all this time creating DNA before they could even run their experiments. Of course labs could clone their own genes, but to put it bluntly, cloning is a pain. It was a significant bottleneck we wanted to overcome.

If a lab needed hundreds of genes, they would pay a lot for them, and they would have to wait a long time. We could develop and supply inexpensive molecular tools to advance synthetic biology, drug discovery, next-generation sequencing (NGS), and DNA data storage, to name a few.Īt the time, synthetic DNA cost around 25 cents a base, which was expensive, and the process was relatively slow, which limited the applications. The Bills invented a fantastic technology to write DNA using silicon, which had tremendous potential to scale output and decrease costs.

LR: Can you give us a brief history of the company?ĮL: Bill Banyai, Bill Peck (The Bills), and I founded Twist in 2013. Lu Rahman chatted with Twist co-founder and CEO Emily Leproust about its path to success. By miniaturising chemistry, and maximising synthesis throughout, it has ramped up the availability and accessibility of synthetic DNA for the biotech and biopharma industries. DNA synthesis company Twist Bioscience has developed a revolutionary, silicon-based approach to building synthetic DNA.

0 kommentar(er)

0 kommentar(er)